Hi All,

Welcome to Levtec Systems first newsletter.

Firstly thank you for subscribing and supporting our products.

This monthly segment will get better with time and our aim is put out informative content that hopefully helps you and some interesting interviews and facts that hopefully enlighten you.

Before we go any further I will give a brief summary of the company. Levtec Systems was formed by myself and my fiancé Chrystal in 2011.We had a first goal of designing the Levtec Tile Levelling System, further to that then branch out into other products for the construction and home renovation sector.

We are a family owned and operated company and with 20 yrs experience as a qualified Wall and Floor Tiler I feel I have some knowledge to share with the industry. I know methods vary and we are always learning and finding ways to improve our work and make our daily tile a lot easier and more profitable.

Pool Installations

In this first edition of the blog we are going to be touching on the very important subject of correct installation of pool tiling systems.

With the conditions that tile installations have to withstand in pool and spa applications manufacturers specifications are ever so important.

We are very thankful to have Laticrete as a contributing manufacturer to the Levtec Blog and also tiling legend Iain “VVO” Middleton, to share his Expert knowledge of this very important area of tiling.

The LATICRETE® Pool, Spa and Fountain System is composed of time and job proven LATICRETE tile installation products which has been successfully installed around the world for 60 years. It provides single source responsibility for these demanding, high performance applications.

The LATICRETE System offers the latest technology in construction materials and methods, delivering superior performance which is backed up by our 10, 15 and 25 Year System Warranties.

The LATICRETE Pool, Spa and Fountain System is designed to be chemical resistant, with shock proof materials that won’t break down or fail. Guaranteed. Click Here to view/download – LATICRETE Pool and Tile Systems Brochure.

Industry professionals rely on LATICRETE proven performance for all of their construction solutions and specification needs – View/download our Swimming Pool Technical Design Manual.

For more information on LATICRETE products, technical support go to www.laticrete.com.au or contact your local LATICRETE Technical Sales here, or call 1800 331 012 for more information.

Iain Middleton – Waterproofing a Pool – Is it necessary ?

Waterproofing and other significant surface preparation is hot on the lips of tile and adhesive manufacturers globally, and the magnitude of the litigation of failures is overwhelming, none more poignant in Australia than the Swimming pool. In a country so well versed in water conservation and salination of the available soil, I find it incredulous that not only is it not recognized by pool builders as important but not even questioned by the end user or client.

Waterproofing and other significant surface preparation is hot on the lips of tile and adhesive manufacturers globally, and the magnitude of the litigation of failures is overwhelming, none more poignant in Australia than the Swimming pool. In a country so well versed in water conservation and salination of the available soil, I find it incredulous that not only is it not recognized by pool builders as important but not even questioned by the end user or client.

Not using garden watering systems, bans and restrictions on such and just the natural ‘lack’ of water generally, while the ‘Auto- leveler’ on the pool pumps fresh water in to compensate for the fact it leaks!

At this point you might wonder if this is just scare mongering ? Concrete after all IS waterproof, isn’t it ? I will come back to this later.

Pools in Australia, and by this I restrict my meaning to ‘concrete’ pools, are more often than not sprayed into a steel reinforced lined ‘shell’. This is either cut out of compacted soil or framed up with any number of materials but wood and corrugated iron are common. It is important for the ‘gunnite’ or ‘shotcrete’ to hit a solid surface as it is sprayed and pumped into position. This a common practice in the USA also. Not surprisingly, Europe prefers ‘poured’ methods. This is by framing precise areas, walls and floor etc, and pumping concrete whilst vibrating it in a number of techniques. This is claimed to make the concrete both denser and therefore better, and leaves a smoother surface. Whatever.

There are of course many types of pools, fiberglass, stainless-steel etc. these all have unique waterproofing issues that I need to cover in another article, penetration points and hydraulic engineering I will leave to my good friends who specialize in such. I have worked with a number of experts in this field.

Quite probably, waterproofing a pool for ‘leaking’ is only one reason, and not really the best reason to spend 4 years of excess water bills on waterproofing a 20K pool shell. The average price to waterproof might be between 10 and 20% of the pool cost. No, it’s the fact that pool water gets into the shell in the first place. Leaching out of the sides and underside of the pool as salt is only a fraction of the issue.

Pool water fluctuates, often wildly in its ph. Even the best injection systems by P or J can malfunction. Sensitive calibration plates can ‘salt’ up and give false readings. In any case, pool water is toxic to concrete, one day being acid, the next alkaline, it’s the most aggressive environment you can install tiles in. That is to say nothing of the effect ph, and the high temperatures of modern pools, has on adhesives. Later for this also.

Waterproofing a pool solves a number of issues, leaking and ph bounce affecting the shell for starters. But it can also create some other mechanical issues that need to be understood. Waterproofing is also very black and white, it is either water proof or not. There are processes that are completely negated by the smallest of pin hole in a membrane style product. Within weeks a pool shell can be completely saturated even after an irreversible and uncorrectable process, stripping the surface back to the shell often the only option.

At this point I need to explain something.

Waterproofing is like a seatbelt. We hope we will never need it. We don’t think, “Well, I’ve never had a crash in 20 years driving, I don’t need one”.

With a pool we hope the air pockets behind the reo-chairs don’t blow, and the penetrations, lights etc, are sound. The glass windows don’t leak and the cars in the garage below don’t get leaching acidified water on them, or the grass and plants don’t die in the garden. We hope the culture of our need to bomb the pool with acid cos its going to be a beaut weekend, will not melt away the steel reo bar in the pool shell saturated concrete. It is even mandatory in Australia to have a pool cover to stop evaporation. It’s a good start.

With a pool, it is recommended to take a number of equally crucial steps to obtain a satisfactory surface on which to tile on, or plaster for that matter. Although there are some qualities of some plasters that maintain a watertight finish in the majority of the pool, usually minus the waterline where the tile meets the plaster, leak zone, waterproofing appropriately can avoid water coming ‘up’ through the shell as in a river edge style pool. Hydrostatic valves are another item also required but not discussed here.

There are 3 or 4 completely different ways to waterproof a pool and in some combinations of these even more useful. Like having 3 seatbelts on, as with a race car, negative and positive hydrostatic issues can be tackled, ph bounce as well as flexibility, as with north facing vanishing edges that heat up to over 100 degrees only to have cold water run over it 100 times a day in mid-summer. Tiles don’t enjoy this, especially highly absorbent ceramic tiles, wrongly but commonly used.

Concrete, you must understand, is like a very dense sponge. Given the chemical cocktail of pool water you have a recipe for disaster. Having to deal with frost and below zero temperatures is thankfully not an issue in Australia, if it was can you imagine the issues with water frozen whilst trapped in a concrete pool shell, I will cover this in another article, although this situation may actually help Pool contractors/builders and tillers to decide to protect the shell in the ways outlined above. I have a plethora of examples of this on my laptop.

So, even if the pool shell is waterproof by and of itself, without ‘waterproofing’, which is highly unlikely, water will migrate into the shell and at the very least penetrate 1/2inch -10/15mm into it, causing the ph acid/alkaline cycle to eat away at the concrete, tile, adhesive and grout. Especially if the water is kept at 30+ degrees, which is very normal in today’s market.

In conclusion, this is not meant to panic anybody, and no doubt I will get critiqued by mail, but it is intended to call to action interested clients and pool professionals generally, also authoritative bodies and legislators. It is written to help tilers protect their reputations and installations, by providing a pathway to best/better practice in the pool industry. Before tiling a pool, check what I’ve said with any tile or adhesive manufacturer, I did.

Kind regards,

Iain Middleton

(V-vo Architectural Mosaics)

Our Tiler of the month: Chris Stenhouse

“Tiles and bathroom design by Justin at Urban Edge Ceramics in Richmond ,Melbourne” – http://www.urbanedgeceramics.com.au

Hi Chris, Thanks for taking time with LEVTEC.

What do you do, what is the name of your company/employer and where do you live?

Hi Michael! I have a small tiling business called Chris Stenhouse’s Wall and Floor Tiling. Happy to put my name to my work! I live in the Bayside area about 40mins south of Melbourne.

Best spot to get coffee there?

Main st Cafe in Mordialloc or Cafe Moto in Seaford. It’s hard to find good coffee at 6:30 in the morning on the way to work!

What are your hobbies/passion outside of the industry?

Running your own show, it’s hard to find some time for extra hobbies! I’m hoping to get back on the drum kit soon, but in the meantime, I try catch up with mates, hang out with my lady and dog, Denzel.

Who was your first boss/mentor?

I did 3 years in domestic for a company based in Emerald who worked all over Melbourne. He had 3 other qualified tilers who I learnt a lot off of each of them. I then did commercial tiling in my 4th year where I also learnt a lot of different methods on a large scale, for example screeding and multi-story units with some supervising roles.

Do you still tile the way he taught or have you adapted your own personal style?

I still tile the using same methods but have extended my knowledge since working for myself which I feel is necessary in this trade as products and standards keep changing to keep up with the changes within the industry.

Although Australia has a great tile industry do you feel there are areas that lack regulation or direction on a trade/installer level?

Definitely a lack of regulation. Tiling needs to be licensed. There needs to be more educated tilers, builders and the general public. People don’t really know what’s involved in the trade. There is a science behind it all. Certain techniques and methods that must be used in order to have a successful, long lasting installation. A lot of damage can be caused by improper installation in tiling and waterproofing. Potentially thousands of dollars worth. Uneducated trades or people who are just lazy and cut corners really bring down the overall reputation of the industry.

Congrats on the feature in the latest issue of the Australian Industry Mag ‘Tile Today’, the images were very impressive. Tell us a bit of how that came about and give a shout out to all people involved with that amazing looking project….

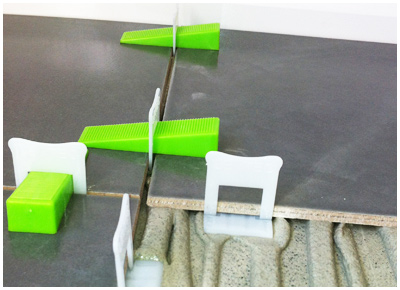

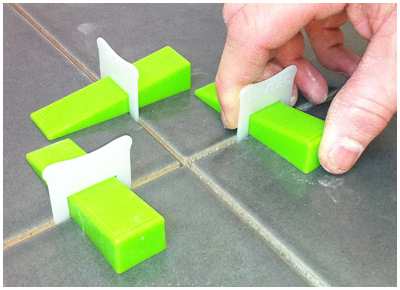

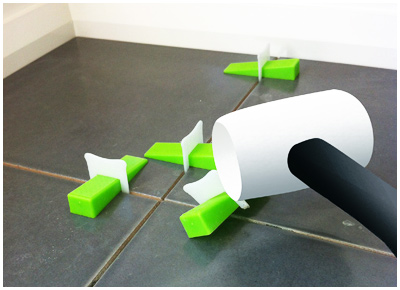

Thanks guys! It was very fulfilling as it was a goal I set myself when I started out on my own. That job the as out in the Melbourne outskirts of Ascot Vale. Large format tiles at 1500x750mm and plank tiles at 150X900mm. I used the Levtec system which made the end result of the job perfect. I acquired the job through word of mouth. It was a owner/builder job, Manny was very particular and the architect was Nicholas Murray and builder on site was Craig Kinney. A lot of credit to them for the way the whole job turned out. Very organised which makes my job alot easier and ends in a great result with satisfaction from all parties.

Ok Chris lastly, what is the best piece of advice you have been given and still use?

Treat every job as if it were your own home. From start to finish. That way everyone is happy. I always make sure the client is happy as it is their house and that is the number one priority.

Thank you.

One thing I really enjoy is the feedback and communication with all industry people, especially the trade’s people. So please keep in touch with feedback, any ideas you have and or questions regarding the industry you would like answered.

Thanks guys,

Regards Michael Gorton.